Industrial Hygiene Management Software

Proactive workplace health and safety requires anticipating, monitoring, controlling and mitigating physical, chemical and biological exposures for a safer work environment.

Optimise Your Industrial Hygiene Program and Performance

Provide industrial hygienists with the necessary data to implement effective control measures. Our industrial hygiene software helps EHS professionals mitigate and anticipate health risks with powerful analytics and reporting tools.

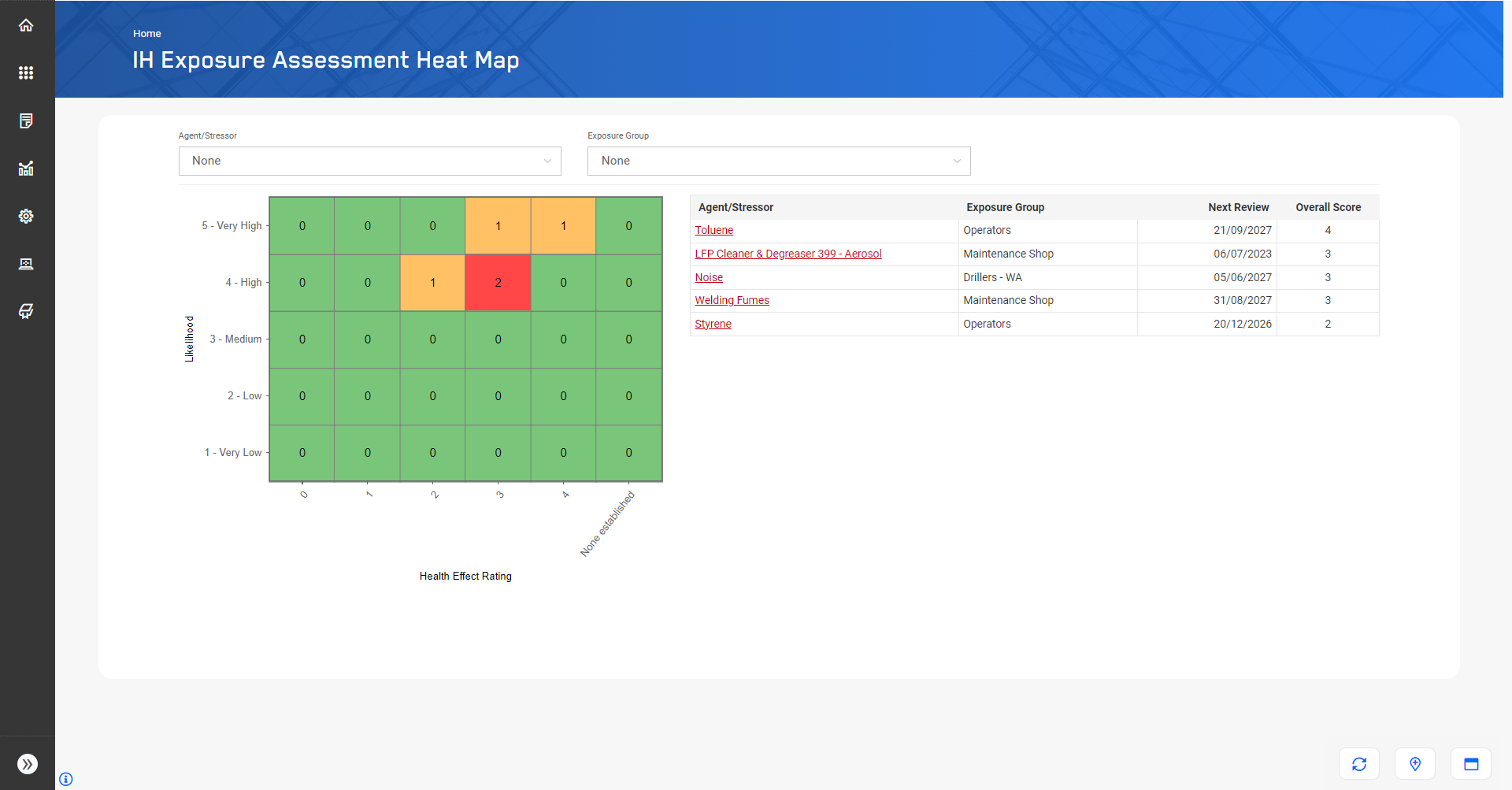

Conduct detailed exposure assessments, develop tailored sampling plans and define similar exposure groups. Manage industrial hygiene systematically by detecting and monitoring workplace hazards to pinpoint areas needing urgent attention.

Transparent

Monitor workplace exposures that may impact workers’ health.

Improving

Anticipate health risks early and apply effective controls.

Consistent

Define and manage exposure groups.

Compliant

Ensure compliance with regulations and standards.

How Can Industrial Hygiene Management Software Help?

Predict, Monitor and Control Workplace Health Hazards and Exposures

- Identify potential hazards that could lead to sickness or compromised air quality and implement corrective actions to prevent harm to workers.

- Improve the efficiency and reliability of industrial hygiene programs with repeatable processes and ensure the integrity of collected data.

- Analyse the progress and effectiveness of industrial hygiene programs to demonstrate controls and measures are effective.

Learn how we tailor our industrial hygiene monitoring platform to meet your specific industry needs.

Reduce Industrial Hygiene Risks With Automated Notifications and Reminders

- Implement effective and successful industrial hygiene processes with automated notifications and reminders for key activities.

- Implement a systematic approach based on internationally recognised principles.

See why Evotix can help drive EHS and ESG transformation at your organisation.

Develop Sampling Plans and Conduct Exposure Assessments

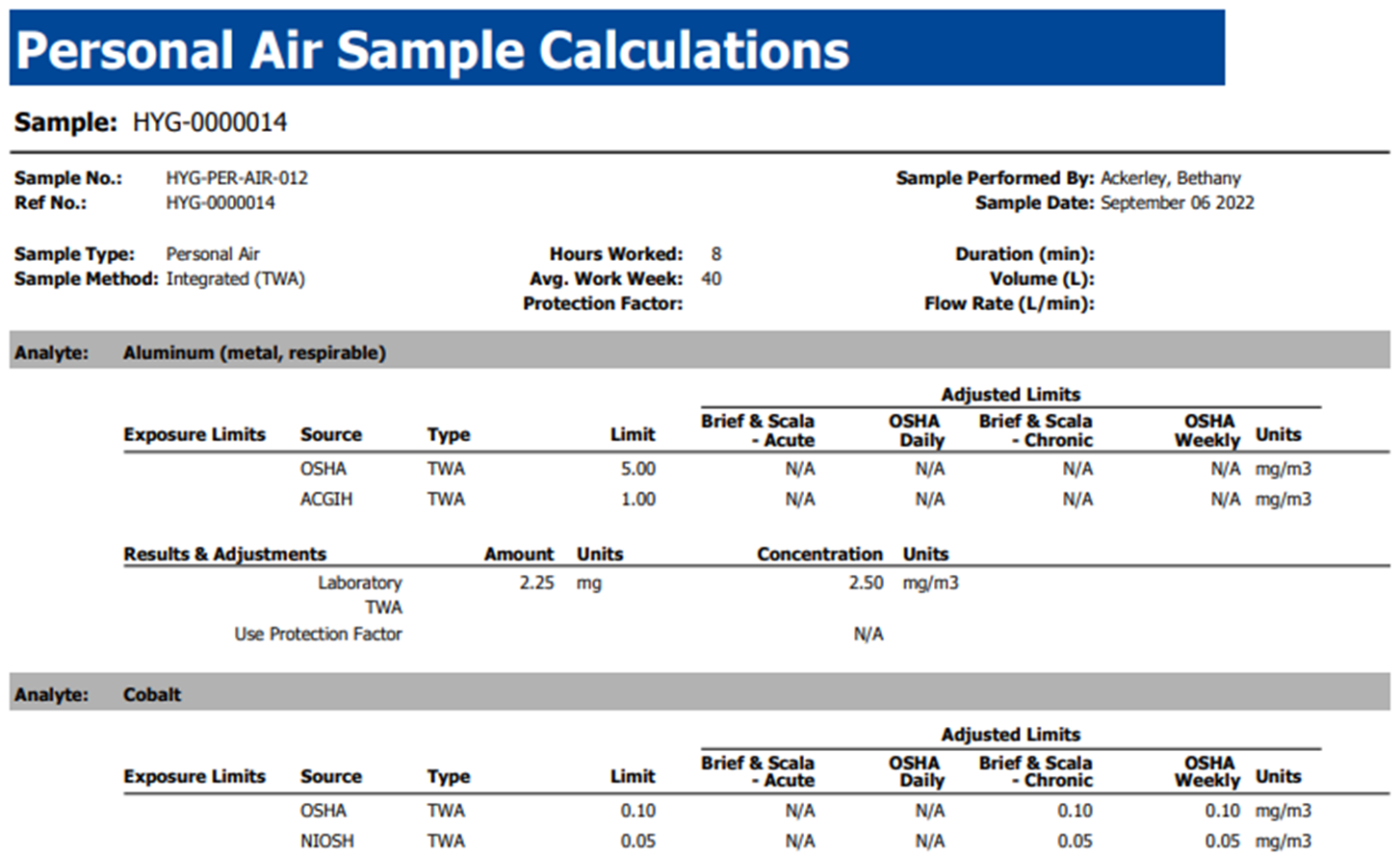

- Perform qualitative and quantitative exposure assessments and manage an array of sample types, including air, noise, wipe, bulk and heat stress assessments.

- Use real-time data to assess exposure levels and compare them to exposure limits, ensuring immediate action when necessary.

- Make critical decisions quicker with seamless access to predefined user lists, such as "Samples Awaiting Laboratory Results," "Samples With Overexposures," "Equipment Requiring Calibration" and "Exposure Assessment Reviews.”

Optimise Your Industrial Hygiene Program With These Tools:

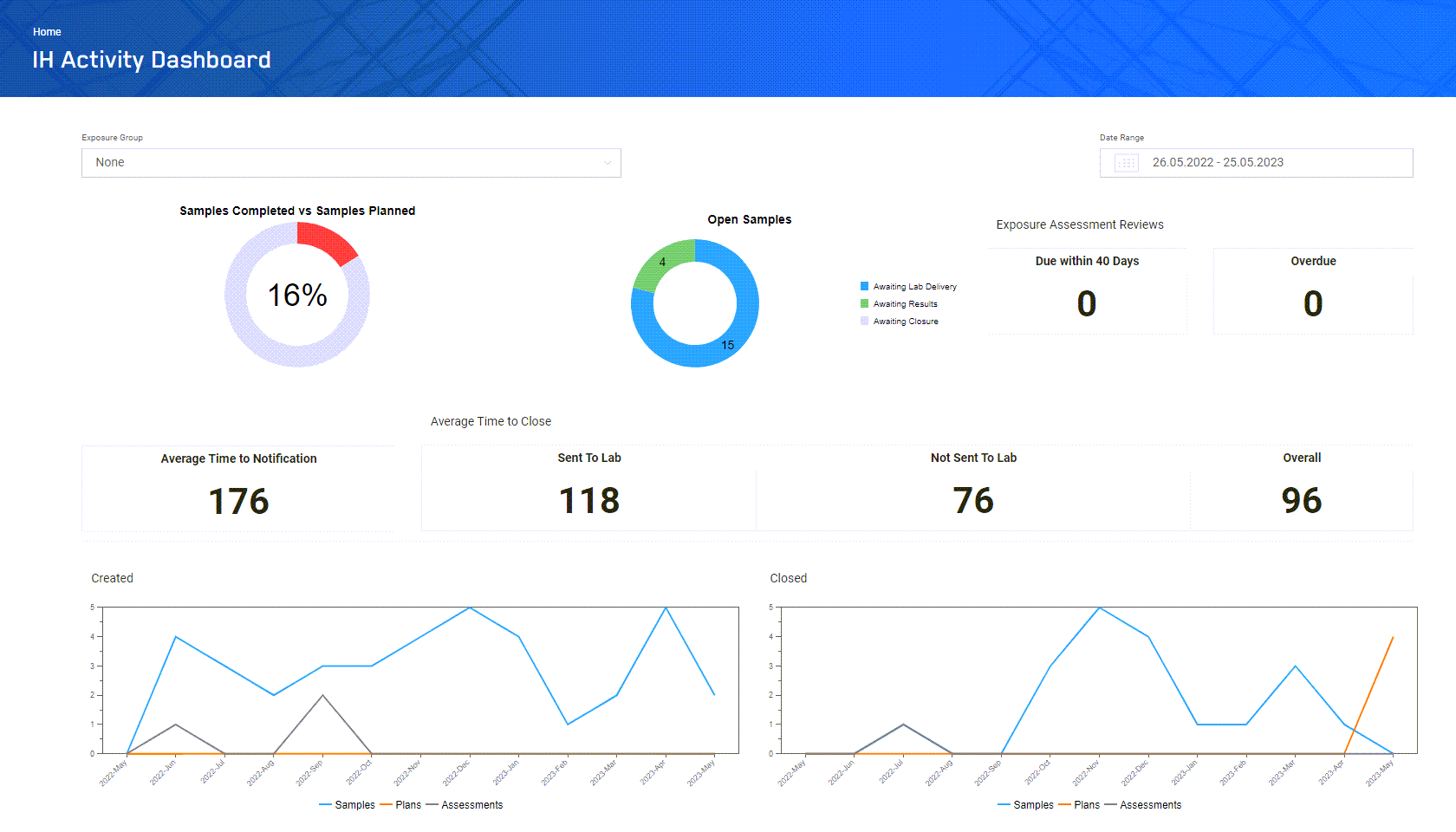

- Data Analytics, Reports and Dashboards: Spot areas requiring immediate attention, such as high-risk exposure assessments or elevated sample results.

- Provide Training and In-The-Flow Information: Educate employees about industrial hygiene to drive improvement and control overexposures.

- Integrate With Action Management: Manage actions related to risk assessment and safety protocols holistically by adopting a cross-functional approach.

- Occupational Health: Provide oversight into all elements affecting similar exposure groups (SEGs), such as health tests and vaccination requirements.

Frequently Asked Questions

What is industrial hygiene in EHS?

Industrial hygiene is anticipating, recognizing, evaluating and controlling workplace conditions that may cause employee injury or illness. Environment, health and safety (EHS) focuses on minimizing workers' exposure to potential hazards in industrial environments.

What are the main components of an effective industrial hygiene program?

What types of hazards do industrial hygiene programs address?

Industrial hygiene programs address a range of hazards and risks in the workplace, including: Chemical (e.g., gases, vapors), Physical (e.g., noise, temperature), Biological (e.g., bacteria, viruses) and Ergonomic (e.g., repetitive motion, improper posture). Read more about 4 key challenge industrial hygienists face and how to tackle them.

What role does technology play in industrial hygiene management?

How often should organizations conduct workplace exposure assessments?

How can organizations ensure ongoing industrial hygiene compliance?